Strip Seal Expansion Joint

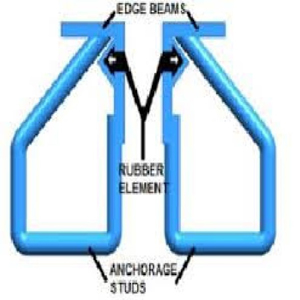

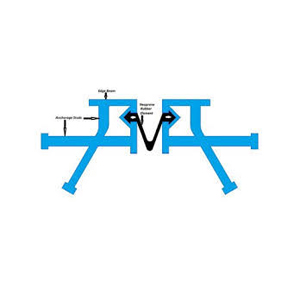

ENTERPRISES provides best Strip Seal Expansion Joints in Hyderabad Strip Seal Expansion Joints consist of 2 edge beams of elastomeric sealing element and anchorages in order to ensure the water tightness of the joint. Strip seals uses have successful performances records all over several years. We use monolithic edge beam, so stability and life of the products increases and also we use tough neoprene rubber Strip as the water barrier in the gap which has the very high life time. These edge beams which protects from damages will cause due to transfer vehicular load to the deck structure. We are appreciated among our clients for low maintenance, sturdy construction and also for high efficiency. High-class materials as per IS and MoRTH Specificaiton are used in order to fabricate these Strip Seal Expansion Joints in order to make it strong and also durable.

COMPANY PROFILE

Sandhya Enterprises which is well Known for ManBridge Expansion Joint Gap 40.0mm (Movement up to 80mm). Bridge Expansion Joint consist of two edge beams with anchorages and with Neoprene sealing element held firmly in the housing of edge beams that guarantee the water tightness the joint. The maximum gap between the edge beams at the road surface when the joint fully opens due to maximum contractions of the deck shall be limited to 80mm for comfortable passage of traffic. The edge beams protects the adjacent bridge deck concrete from damage due to vehicular impact and also transfer the vehicular loads to the deck structures through robust anchorage system. Typical Bridge Expansion Joint is shown in the figure below.

| S. No | Tests | MoRTH Specification Section 2600, Clause 2607 Clause Number | Permissible Limits as per MoRTH Specification Section 2600, Clause 2607 | Relevant Code for Testing Procedure/Method | Results | |

| 1 | Physical Properties – Before Ageing | |||||

| Hardness Test | Table 2600-1 | 58-68 Shore A | IS : 3400 (Part II) | 60-62 Shore A | ||

| Tensile Strength | Table 2600-1 | 11 MPa (Min) | IS : 3400 (Part I) | 17.5 MPa | ||

| Elongation at Break | Table 2600-1 | 350% (Min) | IS : 3400 (Part I) | 415% | ||

| 2 | Ash Content | Cl. 915.1.3, IRC 83 (Part II)2015 | 5 % (Max) | IS : 3400 (Part XXII) | 3.50% | |

| 3 | Polymer Percentage | Cl. 915.1.3, IRC 83 (Part II)2015 | 60 % (Min) | IS : 3400 (Part XXII) | 63.14% | |

| 4 | Polymer | Table 2600-1 | Chloroprene(CR) | ASTM D297 | Chloroprene(CR) | |

| 5 | Compression Set | Table 1 Cl. 915.2 | -28 % (Max) | IS : 3400 (Part X) | 16.22% | |

| 6 | Shock Elasticity | Table 2600-1 | -25 % (min) | IS : 3400 (Part X) | 27.25% | |

| 7 | Tear Propagation Strength | |||||

| Longitudinal | Table 2600-1 | 10N/mm (min | IS : 3400 (Part 17) | 45.22N/mm | ||

| Transvers | Table 2600-1 | 10N/mm (min) | IS : 3400 (Part 17) | 50.24N/mm | ||

| 8 | Swelling behaviour in ASTM Oil No 3 for 70oC for 116 hrs | |||||

| Volume Change | Table 2600-1 | -25 % (max) | IS : 3400 (Part 17) | -16.22% | ||

| Change in Hardness | Table 2600-1 | -20 Shore A (max) | IS : 3400 (Part 17) | -6 ShoreA | ||

| 9 | Physical Properties – After Ageing @ 70oC for 14days | |||||

| Change in Tensile Strength % | Table 1 Cl. 915.2 | – 20 % (Max) | IS : 3400 (Part IV) | -7.13% | ||

| Change in Elongation at Break in % | Table 1 Cl. 915.2 | – 20 % (Max) | IS : 3400 (Part IV) | -14.66% | ||

| Change in Hardness | Table 1 Cl. 915.2 | + 5 Deg (Max) | IS : 3400 (Part IV) | +26 | ||

- Proven record.

- Cost effective solution.

- Ease of installation.

- No mechanical anchors or metal components. Installed by compressing the seal into place.

- Flat top surface.

- Non-serrated top provides a smooth riding surface.

- Neoprene rubber

Provides excellent resistance to weather, sunlight, UV, and chemical (Neoprene only).nd some Other Rubber Product

This shall be e Hot Rolled Steel Section or Cold Rolled Cellular Steel Section with suitable Profile to mechanicallay Lock lock the sealing elementin place throughout the normal movement cycle. Further, the configuration shall be such that the section has a minimum thickness of 10mm all along its cross section (Flange & Web). Thickness of lips bolding the seal shall not be less than 6mm, the minimum height of the edge beam section shall be 80mm.The minimum cross section area of the edge beam shall be 1500mm2

- 65mm Width x82mm Hightx10mm thick

- 75mm width x82mm Height ex10mm Thick

Anchorage

Edge beam shall be anchored to the deck by reinforcing bars, or anchor plates cast in concrete or a combination of anchor plate and reinforcing bars, Anchor bars, shall engage the main structural reinforcement of the deck and in case of anchor plates or loops, this shall be achieved by passing transverse bars through the loops or plates.

The minimum thickness of anchor plate shall be 12mm, Total cross section are bar on each side of the Joint shall no be less than 1600mm Sq. per meter length of the Joint and the centre to centre spacing shall not exceed 250mm.The Ultimate resistance of each anchorage shall not be less than 600KN/M in any direction

Material

The steel for edge beam shall conform to any of the steel grade corresponding to RST 37-2 or 37-3 (DIN), ASTM A36 or A588, CAN/CSA Standard G40.21 Grade 300 W or equivalent

Anchorage steel shall conform to IS:2062 or equivalent.

All steel sections shall be protected against corrosion by hot dip galvanising or any other approved anticorrosive coating with a minimum thickness of 100 micronts. We are of strip seal element shall conform to Clause 915.1 of IRC:83 (Part-II)

- Edge beam shall be placed in such a manner that the grooves are positioned properly.

- Steel structure and main reinforcement shall be anchored with proper welding.

- Alignment shall be checked for both steel structures, if required by using suitable device.

- Recess shall be filled with high quality of the concrete not less than M 35 grade.

- If any installation brackets were used, shall be removed after the concrete has cured.

- Sandhyaflex elastomeric strip seal shall be cut into the required length and inserted between the beams by using the proper device and to be ensured that the bulb of the seal is getting into the steel grooves of the both edge beams.

- When the recess concrete has become set, a sturdy ramp shall be placed over the joint to protect the exposed steel beams and the elastimeric seal from the traffic.

- Without carriageway surfacing, expansion joint shall not be exposed to traffic loadingbacked up by Fully Fledged Laboratory Facilities in order to conduct various Quality Tests from Raw Materials Stage to Finished Product Stage in order to ensure Superlative