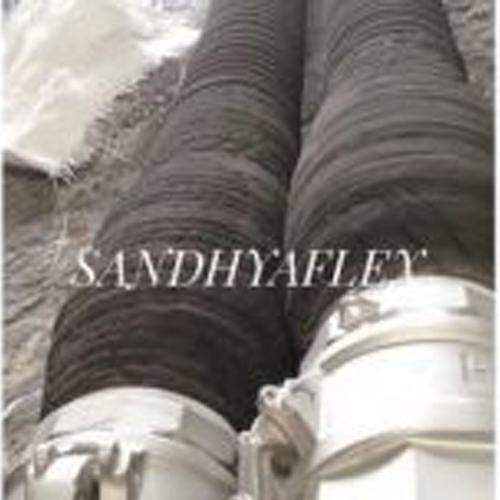

Chemical Rubber Hose

Chemical Rubber Hose Pipe is Designed to handle a wide range of chemicals, acids, alkalies and alcoholic, mineral acids, aqueous solution of inorganic materials during production and their transferring operations.Paras Rubber Hose India is a credible Rubber Hose Pipe manufacturer in India. We offers a wide range of Chemical Rubber Hose Pipe by using high grade material.

Construction:

Lining

Uniform seamless tube of EPDM, Thiokol, Chloroprene, Butyl, SBR, NBR, natural/synthetic/blend rubber compound or a blend depending on the liquid for which the hose is intended to be used.

Reinforcement

Plies of rubber coated woven textile or braided synthetic yarns with or without helical galvanized steel wire.

Cover

Smooth, fluted or fabric marked finish with suitable rubber compound, resistant to weather.

Types

Type 1 for conveying dilute chemicals.

Type 2 for conveying concentrated chemicals.

Pressures:

Type 1 W.P. of 1.00 MPa & B.P. min.3.15 MPa .

Type 2 W.P. of 1.00 MPa & B.P. min.4.00 MPa

Chemical rubber hose is mainly used for chemicals conveyance and chemical sewage treatment in chemical plant, paint factory, pharmaceutical factory, chemical tanker, sewage treatment plant and other industries. It can be used for suction and discharge of most chemicals and it has excellent bending property. It is composed of three parts: tube, reinforcement and cover. Tube is

Chemical rubber hose is suitable for high pressure working conditions because of its reinforcement.

Features Of Chemical Rubber Hose:

- Resistant to high pressure.

- Resistant to corrosion and static.

Features Of Chemical Rubber Hose:

Resistant to high pressure.

- Resistant to corrosion and static.

- Resistant to kink.

- Without deformation and dissolution.

- Excellent bending property and abrasion resistance.

- Outstanding flexibility.

- Long service life.

| The specification of chemical rubber hose | |||||||||||||

| Hose code | ID | Reinforcement | OD | Length | Bend radius | Working pressure | Vacuum pressure | Weight | |||||

| inch | Mm | Ply | Inch | mm | ft | m | inch | mm | Psi | mmHg | kg/m | ||

| SANDHYAFLEX-01 | 1 | 25.4 | 2 | 1.535 | 39.0 | 200 | 60 | 7 | 175 | 200 | 736.6 | 1.17 | |

| SANDHYAFLEX -02 | 1-1/4 | 31.8 | 2 | 1.787 | 45.4 | 200 | 60 | 8 | 200 | 200 | 736.6 | 1.33 | |

| SANDHYAFLEX -03 | 1-1/2 | 38.1 | 2 | 2.035 | 51.7 | 200 | 60 | 10 | 250 | 200 | 736.6 | 1.58 | |

| SANDHYAFLEX -04 | 2 | 50.8 | 2 | 2.575 | 65.4 | 200 | 60 | 14 | 350 | 200 | 736.6 | 2.24 | |

| SANDHYAFLEX -05 | 2-1/2 | 63.5 | 2 | 3.091 | 78.5 | 200 | 60 | 17 | 425 | 200 | 736.6 | 2.79 | |

| SANDHYAFLEX -06 | 3 | 76.2 | 2 | 3.634 | 92.3 | 200 | 60 | 21 | 525 | 200 | 736.6 | 3.71 | |

| SANDHYAFLEX -07 | 4 | 101.6 | 4 | 4.728 | 120.1 | 200 | 60 | 28 | 700 | 200 | 736.6 | 5.26 | |

| SANDHYAFLEX -08 | 6 | 152.4 | 4 | 6.815 | 173.1 | 200 | 60 | 42 | 1050 | 200 | 736.6 | 8.74 | |